01

Small size Horizontal toggle clamp GH-201

This is our smallest horizontal toggle clamp in the Level series, which we call it mini toggle clamp, horizontal toggle clamps, woodworking toggle clamp, and so on. The bar open angle is 90 degrees, and the handle open angle is 80 degrees. The base plate has four mounting holes for securing the clamp with screws from above, and the pressure pad is made of black rubber. The principle of this small clamp is to secure the workpiece by adjusting the angles of the handle and pressure pad. Its main feature is to stably hold the workpiece that needs to be worked on, ensuring stability. This is the smallest horizontal clamp and has a wide range of applications. Our company, Zhaoqing Wise Hardware Co., Ltd, selects high-quality iron raw materials for cutting, stamping, assembly, and a series of processes to assemble this widely used fixture. For customers with special requirements, high-quality stainless steel materials can be chosen. No matter what your needs are, we can customize a solution for you.

3. Manufacturing processes of.

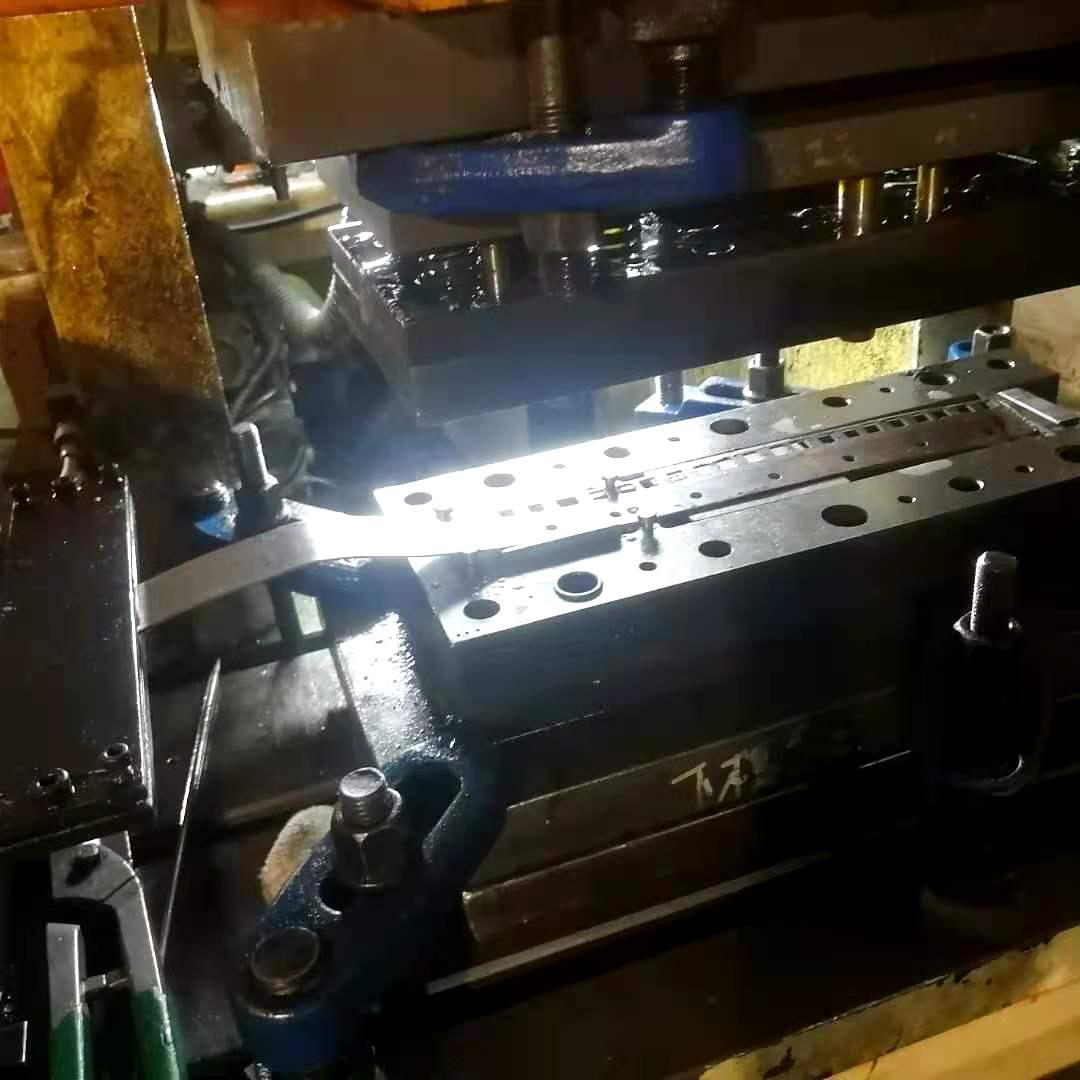

- **Cutting**: Raw materials are cut to the required shape and size using techniques such as cutting, shearing, or punching.

- **Machining**: Parts of the toggle clamp may need to be machined to achieve the desired shape and precision. This can involve processes like milling, turning, drilling, and grinding.

- **Forming**: Certain parts may need to be formed using processes like bending or stamping.

- **Welding**: Assembling different components of the toggle clamp may involve welding or other joining techniques.

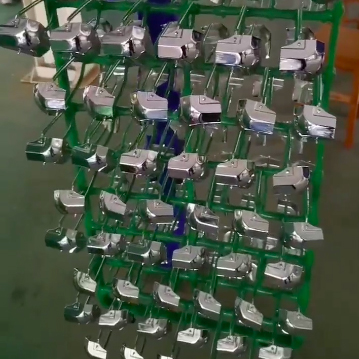

- **Surface treatment**: Parts may undergo surface treatments such as painting, powder coating, or plating for corrosion resistance and aesthetics.

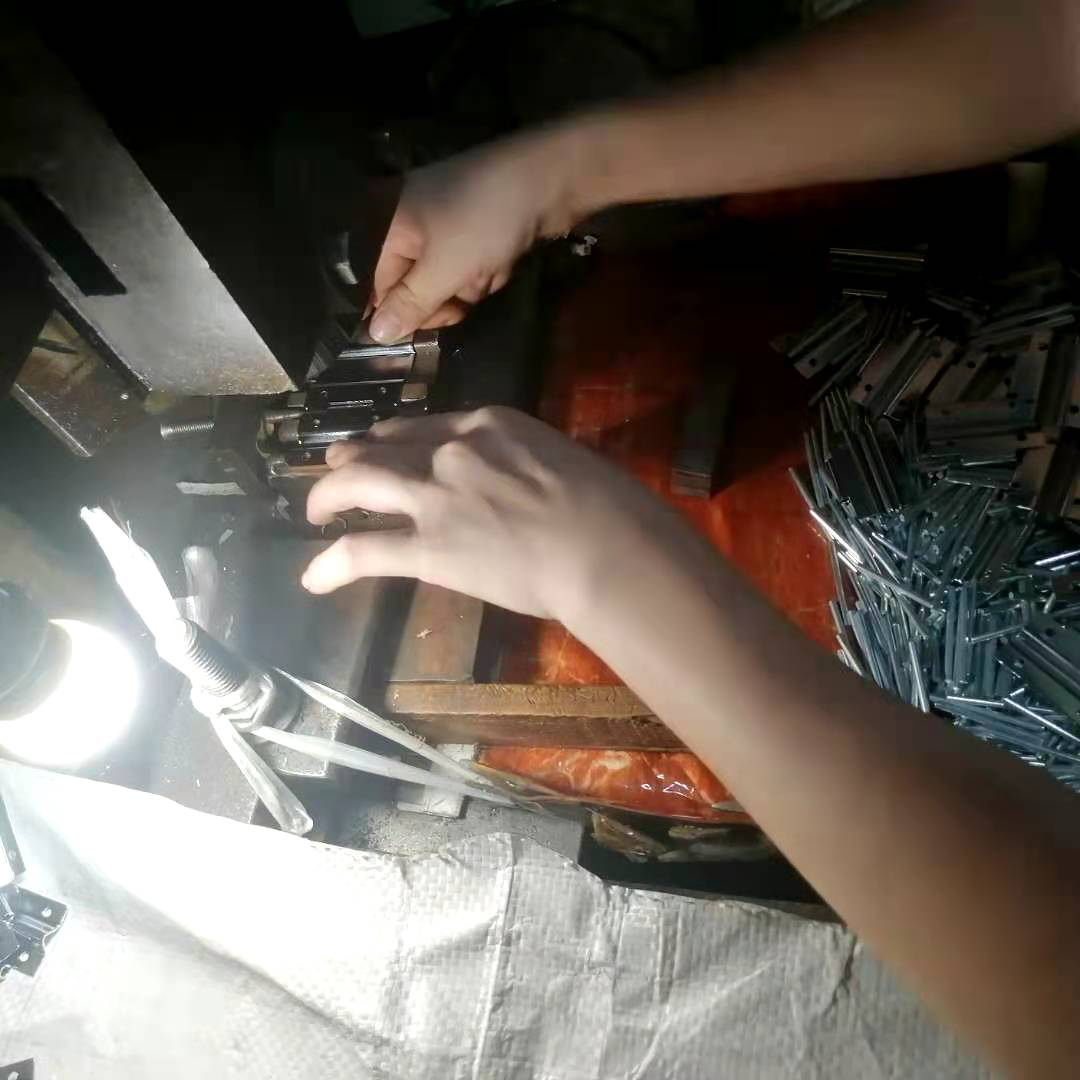

4. **Assembly**: Once all the individual components are ready, they are assembled together to create the final toggle clamp. This may involve using fasteners like screws, nuts, and bolts.

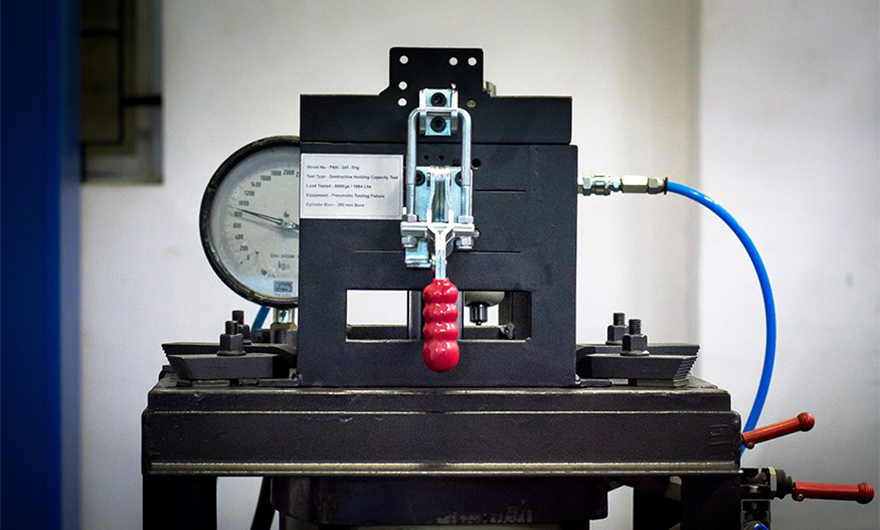

5. **Quality control**: It's essential to perform quality checks at various stages of production to ensure that the toggle clamps meet the required specifications and standards.

6. **Testing**: The finished toggle clamps should undergo testing to ensure they function correctly and meet the performance requirements.

7. **Packaging and shipping**: Once the toggle clamps pass quality control and testing, they are packaged appropriately for shipping to customers.

Please note that producing a toggle clamp requires precision engineering and manufacturing expertise. It's recommended to consult with professionals or companies specializing in metal fabrication and manufacturing if you are considering producing toggle clamps for commercial purposes.