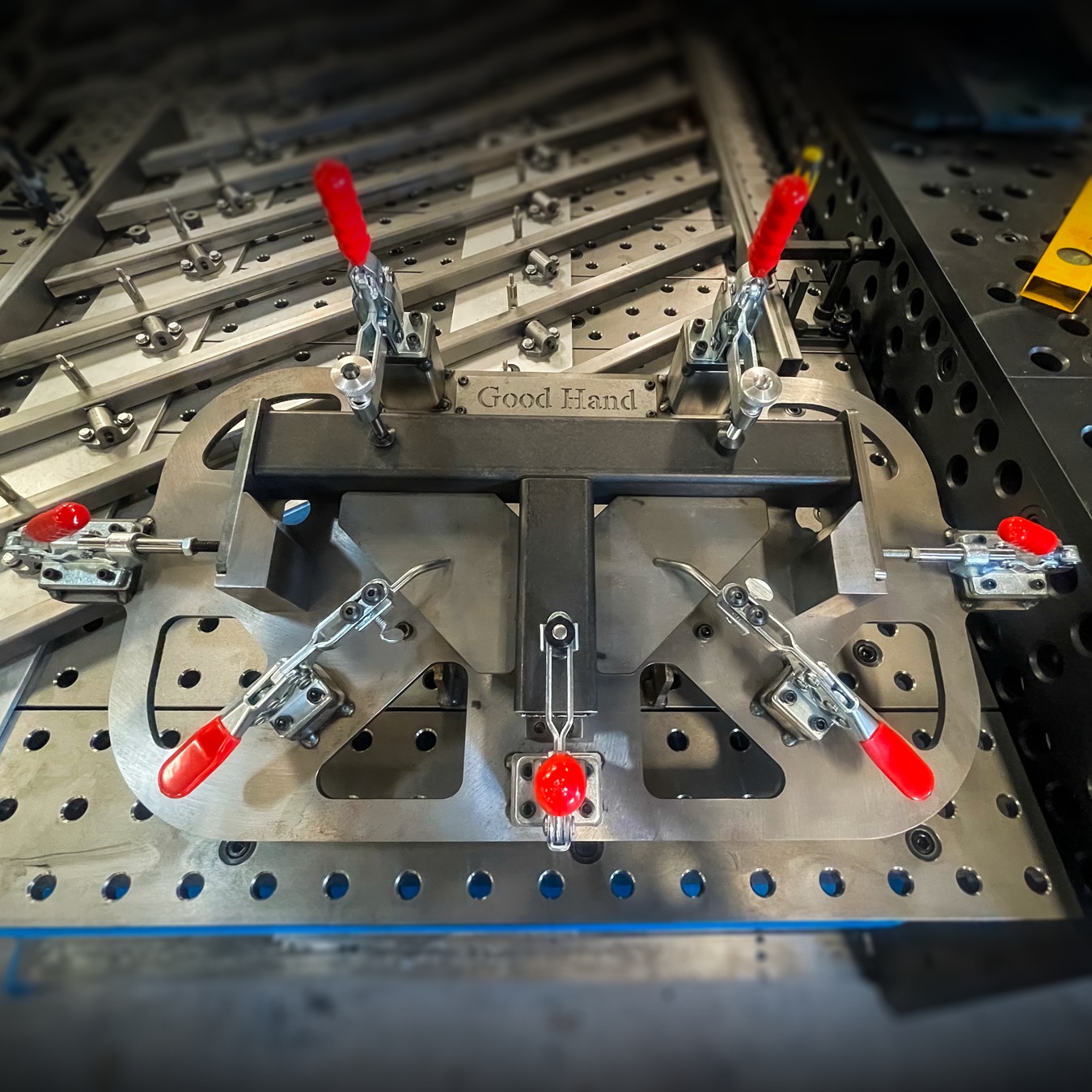

Vertical Toggle Clamp GH-101-A

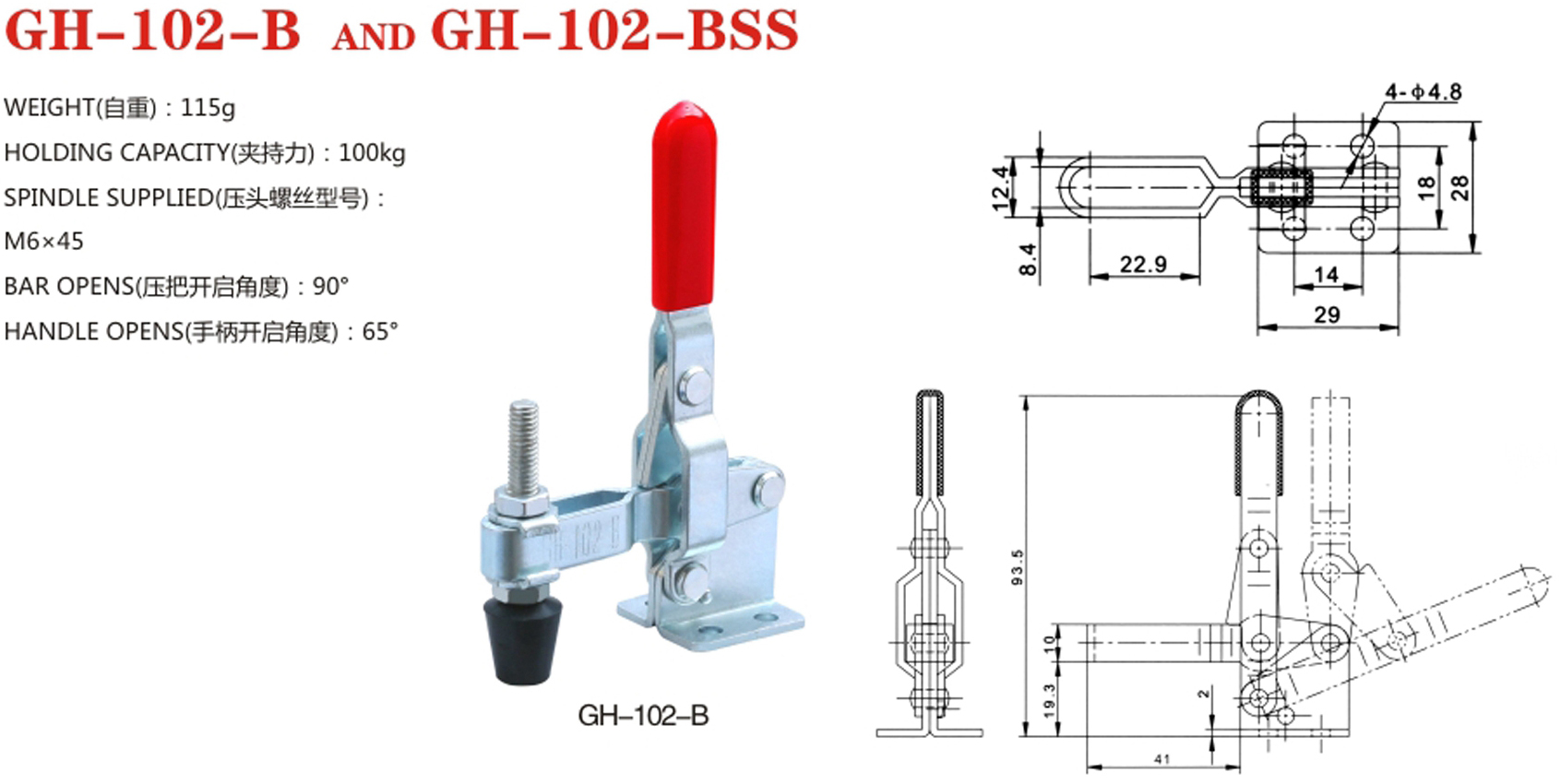

Hold-down clamp GH-101-B is a side-mount hold-down toggle clamp with a U-shaped clamping bar. It has a holding capacity of 100Kg/220Lbs, a natural state opening of 90 degrees, and a zinc-plated finish. The handle is red, and the mounting hole diameter is 4.5mm, with a mounting hole distance of 20mm x 14mm (LW). The rubber cushion thread size is M6 x 38mm, the clamp bar length is 25mm, and the clamp size is 119 x 30 x 100mm (LW*H). The grip has a minimum 90-degree angle for easy loading and unloading, and the material is cold-rolled carbon steel with a zinc-plated coating for corrosion resistance.

Whats the difference between manual toggle clamps and other type of toggle clamp.

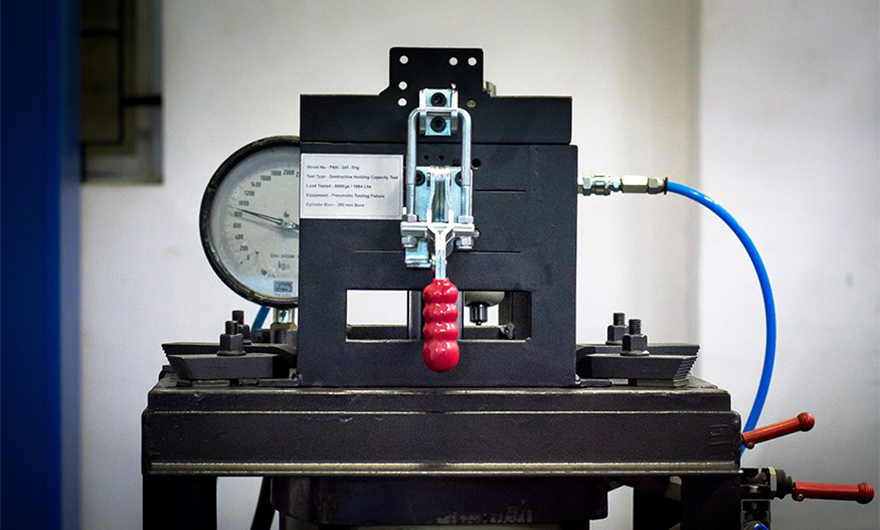

A manual toggle clamp is a type of toggle clamp that is operated manually, typically by hand, to secure an object in place. Other types of toggle clamps may be operated using pneumatic or hydraulic power, or may be automated using electrical or mechanical systems.

One of the main differences between a manual toggle clamp and other types of toggle clamps is the way in which they are actuated. Manual toggle clamps typically use a lever or handle that is turned or pulled to apply pressure to the object being clamped. Other types of toggle clamps may use a piston or cylinder to apply pressure, or may be controlled using a switch or button.

Another difference between manual toggle clamps and other types of toggle clamps is the amount of force that they can apply. Manual toggle clamps are typically limited by the strength of the operator, while other types of toggle clamps can apply much greater forces using pneumatic or hydraulic power.

Finally, manual toggle clamps are often more portable and easier to use in tight spaces than other types of toggle clamps. They are also typically less expensive and more widely available than other types of toggle clamps.

In summary, the main differences between a manual toggle clamp and other types of toggle clamps are the way in which they are actuated, the amount of force that they can apply, and their portability and ease of use.